There are three main fan laws: the law of affinity, the law of volume, and the law of pressure. These laws relate the fan speed, the fan diameter, the air flow, the static pressure, the power consumption, and the air density. By using these laws, engineers can calculate the resulting values of these parameters when one or more of them are changed. For example, if the fan speed is increased by 10%, the air flow and the static pressure will increase by 10% and 21%, respectively, while the power consumption will increase by 33%.

Fan laws analysis help engineers to use fan curves, which are graphical representations of the fan performance at different operating points. Fan curves show the relationship between the air flow and the static pressure, as well as the power consumption and the fan efficiency, for a given fan speed and air density. By using fan curves, engineers can determine the best operating point for a fan in a system, as well as the effects of changing the system resistance or the fan speed.

Fan laws analysis is an important tool for thermal management of electronics, as it can help engineers to ensure that the fans provide adequate cooling for the devices, while minimizing the noise and the energy consumption. Fan laws analysis can also help engineers to troubleshoot fan problems, such as reduced air flow, increased noise, or overheating.

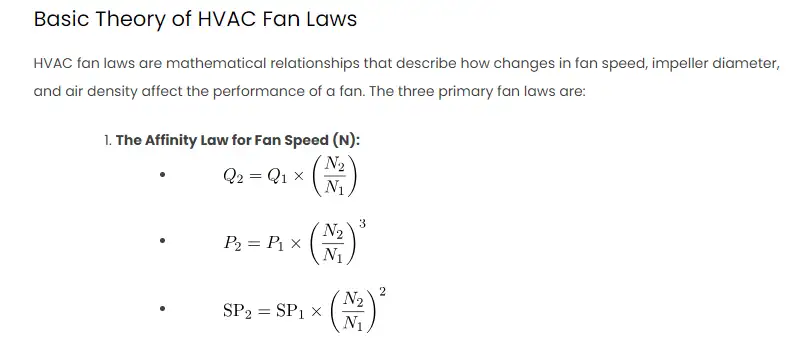

Basic Theory of HVAC Fan Laws

HVAC fan laws are mathematical relationships that describe how changes in fan speed, impeller diameter, and air density affect the performance of a fan. The three primary fan laws are:

- The Affinity Law for Fan Speed (N):

-

- The Affinity Law for Impeller Diameter (D):

-

- The Affinity Law for Air Density (ρ):

-

Where:

is the flow rate,

is the power,

is the static pressure,

is the fan speed,

is the impeller diameter, and

is the air density.

Procedures and Application in Excel

Scenario:

Let’s consider a scenario where we have a fan with the following initial conditions:

(Cubic Feet per Minute)

(Horsepower)

(Water Gauge)

Now, let’s consider a new set of conditions:

Excel Formulas:

We can use Excel to calculate the new values based on the fan laws. Let’s set up a table in Excel:

| Parameter | Initial Value | New Value (Excel Formula) |

|---|---|---|

| Flow Rate (CFM) | 1000 | =A2*(E2/B2) |

| Power (HP) | 2 | =B2*(E2/D2)^3 |

| Static Pressure (inches WG) | 1.5 | =C2*(E2/B2)^2 |

Fill in the formulas in Excel, and you’ll get the new values for flow rate, power, and static pressure.

Excel Results:

- New Flow Rate (

): 1250 CFM

- New Power (

): 3.857 HP

- New Static Pressure (

): 2.8125 inches WG

MATLAB Comparison:

To compare the results, we can perform similar calculations in MATLAB using the same fan laws. The MATLAB code for the scenario would be:

Q2 = 1000 * (1500/1200);

P2 = 2 * (1500/1200)^3;

SP2 = 1.5 * (1500/1200)^2;

Running this MATLAB code will yield similar results to those obtained using Excel.